Electronic waste is growing faster than any other type of waste in the world. Despite several initiatives from the EU, major shortcomings remain in recycling – which is why the lifecycles of electronics must be extended to ensure resources are fully utilized.

Every year, the world throws away electronics weighing as much as its heaviest structure – the Great Wall of China. Within the EU, less than 40 percent of materials are properly handled, and most member states remain far from reaching their collection targets.

This summer, the EU began reviewing the WEEE Directive (Waste Electrical and Electronic Equipment) to improve recycling and curb the growing mountain of waste. The Circular Economy Act has also been released for public consultation, inviting feedback from citizens. The hope is that the new legislation will make it more advantageous and competitive to both reuse and recycle electronics within Europe.

But despite good intentions, the reality is complex. For these systems to work, the entire chain must function – from product design to collection, logistics, and material recovery.

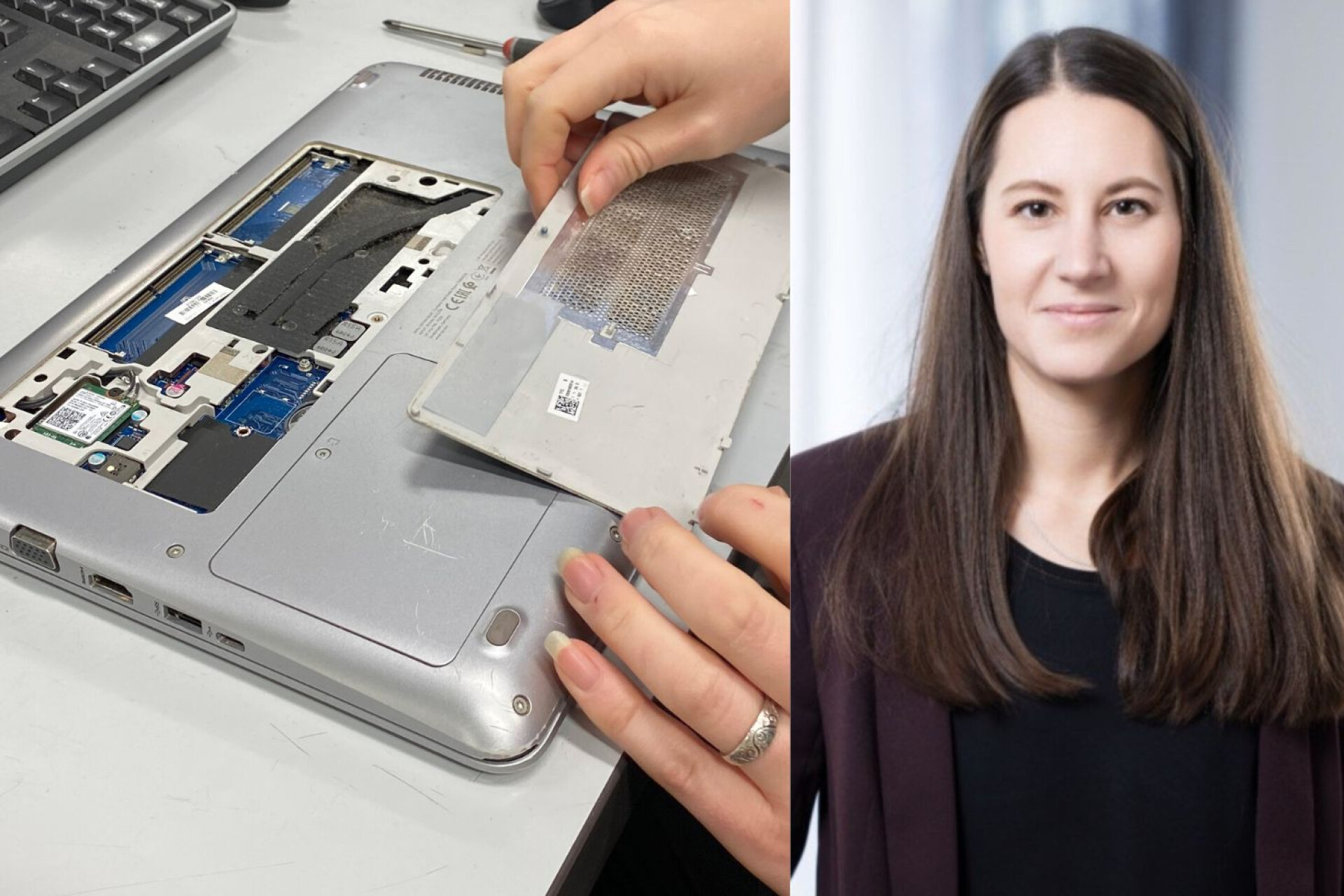

“Thanks to thorough repairs, an average of 95 percent of all IT equipment that comes to us gets a new life with a second user,” says Sebastian Holmström, Head of Sustainability at Inrego. “But far from all electronic products reach us circular actors, and even the last five percent that cannot be reused must be part of a functioning loop. Only then does the circular economy truly work.”

“Electronics – a complex but valuable resource for recycling”

When Inrego sends electronic components that can no longer be repaired for recycling, one of the final destinations is Boliden’s smelter in Rönnskär – one of the world’s largest smelters for electronic recycling.

Rönnskär has the capacity to recycle up to 120,000 tons of electronic waste per year, equivalent to around two million mobile phones per day. Materials recovered include copper, zinc, gold, silver, and other metals from old circuit boards, computers, and phones.

“Electronics are a complex but valuable resource for recycling,” says Sandra Lindström, Environmental and Public Affairs Manager at Boliden Smelter. “There are so many different materials in such a small space – plastics, glass, and multiple layers of metals. The materials are hard to separate, and the plastics are contaminated.”

Low profitability in recovering more metals – and high emissions from recycling phones

To prevent everything from being lost, the contaminated plastics produced during recycling are currently used as fuel in the smelting process – but unfortunately, this generates very high emissions. As the EU gradually phases out free emission allowances under the EU ETS, these emissions are becoming increasingly costly. Many smelters therefore choose to focus on larger quantities of cleaner metals, such as copper pipes.

“To truly increase the recycling rate, we need significantly better product design,” Sandra explains.

“Some metals in electronic waste exist in such small quantities that it’s neither technically nor economically feasible to recycle them today. We need financial incentives that drive the transition. We’re one of the few players focusing on this as our niche, but if it became profitable to invest in technology that recovers more metals, I believe the entire recycling industry would change,” she adds.

Companies that think smart about IT gain a competitive advantage

Even though the recycling process for electronics generates significant emissions, 80–95 percent of an IT product’s total lifetime emissions occur during the production phase. These recycling challenges highlight the importance of circular systems where products are kept in use for as long as possible.

By selling equipment they no longer use and purchasing part of their IT environment as refurbished, companies can help accelerate the shift toward a circular IT economy – while saving both money and emissions.

“It’s easy to think sustainability is only about the climate, but this is just as much about economics,” says Sebastian Holmström. “When companies sell their used IT to us, they receive market-value payment, which means they recover part of their initial investment. That gives them both reduced emissions and financial savings – strong competitive advantages in today’s market.”

Contact Inrego to sell your used IT equipment – or check out our range of refurbished IT products, at half the price of brand-new!